K 2019 - OCTOBER 23, 2019 Dusseldorf

We will be present as visitors to K 2019, the international fair for plastics and rubber that will take place in Dusseldorf, Germany. This appointment will allow us to learn about the novelties in the field of plastic, rubber and machines for processing them for our continuous research in the sector.

Dream Gadget Design Contest

DREAM project partners would like to produce a gadget that could remind them the first time they met: a bottle opener which is the symbol of the project kick-off meeting in Finland.

For this reason, they would like to have the sentence “Hölkyn Kölkyn”, together with the project’s logo, written on it.

The best design will be assessed by a technical committee, composed by Poly-Shape and Warrant Hub, and will be awarded with a 3D-printer i3 Megas Anycubic.

Do you want to contribute to design this object? We will make your work a reality!

Send your work to dreameuproject@gmail.com

Deadline: 31st August 2019

For more information, please visit: http://www.dream-euproject.eu/gadget-design-contest/

Dream Summer School - JUNE 3-7, 2019

As member of the Dream Consortium, R.B. has participated in the organization of the Summer School on Additive Manufacturing, with a speech on “Main applications and problems of SLM technology in tools production”.

All participants were offered a guided tour of the company premises and a practical experience in the workshop, on the removal of a finished 3D-printed job.

More details and pictures on the event are available at: http://www.dream-euproject.eu/summer-school-gallery/

MECSPE 2019 - MARCH 28-30, 2019 Parma

We look forward to seeing you at MECSPE 2019 – From 18 editions MECSPE is the biggest event dedicated to innovations for the manufacturing industry. The fair is specialized in the design and manufacture of die-casting molds for aluminum, zamak, magnesium and injection molds for plastic materials. You can find us in the Eurostampi pavilion – PAD. 6

H2020 projects

Thanks to the constant commitment to Research and Development activities, MOLD&MOLD is successfully participating in two Horizon2020 projects financed by the European Community.

DREAM project

The first was started in 2016, in collaboration with public and private partners from six countries of the European Union (Eos, Ferrari and the University of Modena and Reggio Emilia, just to name a few). The project has made it possible to develop Powder Bed Fusion technology (titanium, aluminum and steel powder laser fusion), thereby obtaining significant improvements in performance in terms of speed, costs, material use and reliability.

POWDER project

The second project was presented at the end of 2017 and is related to the development of a special powder to expand the target of customers who could potentially benefit from SLM technology. In this way, it will be possible to extend the benefits connected to the presence of conformal cooling channels (reduction in the cycle time and greater production efficiency) also to those customers that up until now were excluded. In February 2018, MOLD&MOLD was awarded the first phase of project financing by the European Community, and is currently developing the second phase.

Learn more about our R&D department

26th FAKUMA - October 16–20, 2018 Friedrichshafe

Fakuma Friedrichshafe

International trade fair for plastics processing.

More than 1800 exhibitors will present their international offers at the leading technical event on a world-wide level for the processing of industrial plastics. Fakuma will take place in the Friedrichshafen exhibition center between October 16 and 20, 2018.

Attention will be focused on the most recent technologies that promise highly advantageous benefits as well as processes and instruments for efficient plastic processing using injection molding, extrusion, thermoforming and 3D printing.

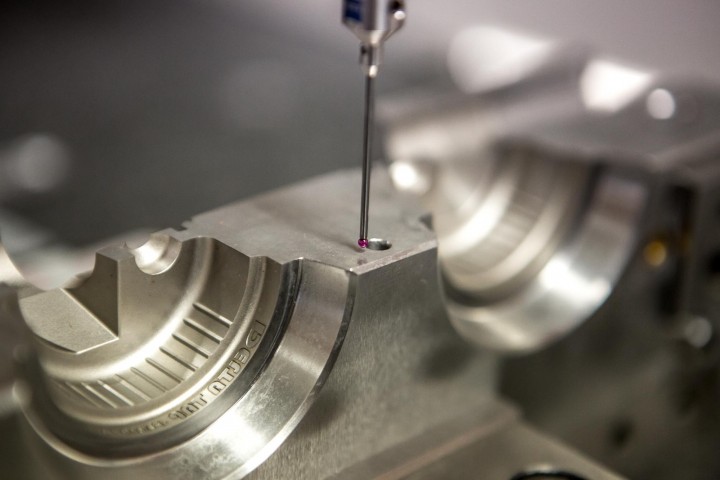

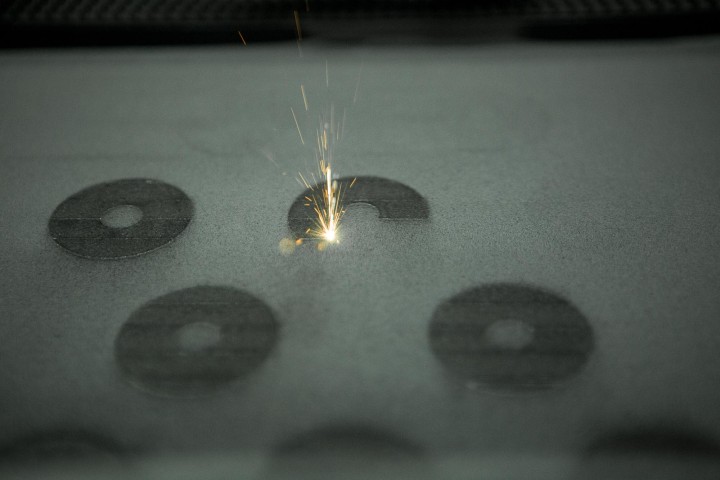

More efficient molds with "Selective Laser Melting"

Why are our molds more efficient?

Thanks to Selective Laser Melting, we are able to create molds that have special internal channels that guarantee extremely quick cooling of the obtained part. An extraordinary result, which makes it possible to drastically reduce cycle times and increase plant production volumes in an inversely proportional manner.

Based on the Additive Manufacturing principle, which is commonly known as 3D printing, SLM makes it possible to eliminate traditional manufacturing constraints, offering the designer maximum freedom in terms of the implementability of shapes and the complexity of geometries.

With respect to conventional methods, which are based on in-mold casting or the removal of material from a raw form, Selective Laser Melting technology consists in layer-by-layer steel (or other metal) powder-laser fusion, according to the points defined by the 3D design, until obtaining the final object.

Learn more about the technology

MEDTEC EUROPE April 17-19, 2018 - Messe Stuttgart, Germany

Medtec Europe is the preeminent medical technology platform showcasing the key trends and insights across the entire supply chain of the medical technology industry.

MECSPE 2018 - MARCH 23-24, 2018 PARMA

We look forward to seeing you at MECSPE 2018 – in the Eurostampi pavilion, a trade fair specialized in the design and implementation of molds for die-cast aluminum, zamak, magnesium and injection molds for plastic materials.

PAV. 6 – C26